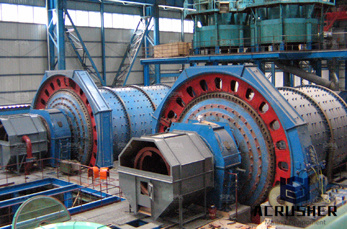

Calculate Ball Mill Grinding Capacity

The sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying empirical equations or factors based on ...

WhatsApp)

WhatsApp)

The sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying empirical equations or factors based on ...

Aug 09, 2016· Industry News. how to calc ulate volume in ball mill filling. Engineering Consulting Mineral Processing Test Mines Design Equipment Manufacture ...

A Study on the Technique of Measuring the Fill Level, A method of measuring the fill level based on the vibration signal of the mill shell is researched in this ...

Aug 03, 2016· wet ball mill calculations for fill volume Wet Ball Mill Calculations For Fill Volume,ball mill dynamic load calculation.

Quick and Easy Black Powder Ball Mill How to optimize a 6 pound ball mill to safely and Quick Easy Black Powder Ball Mill To load the mill jar optimally, fill it ...

Optimum Fill Level In Ball Mill greenrevolutionorgin. Optimization of mill performance by using online ball and, saimm conditions such as mill speed or balls ...

Ball mill fill level electronic ear location Page 1 of 1. Ball mill fill level electronic ear location. In Single chamber ball mill for clinker grinding what is ...

Mill Charge Load Calculation Stone Crushing . Mill Charge Load Calculation; ball load, charge level and mill speed also play an important part as New Method to ...

The Classification of Ball Bearings, Roller US Customs and Border, how to fill in a ball mill,In 1883, Friedrich Fischer created the ballgrinding machine, a ...

Mile High Nordic Ski Education Foundation The Mile High Nordic Ski Education Foundation is a 501(c)(3) nonprofit (EIN: ), allvolunteer group that ...

Know More ... fill factor chart for ball mill balls imsrcoin generation grinding unit, Choosing the fill factor and ball grad, ie separation of the multitude of ...

wet ball mill calculations for fill volume sskpropertiin. calculation of filling volume in ball mill calculation of filling volume in ball mill Description : wet ...

Soft sensor for ball mill fill level based on uncertainty ... Soft sensor for ball mill fill level based on uncertainty ... reasoning of cloud model to improve the ...

How to safely and effectively use a ball mill to grind pyrotechnic chemicals and black powder. Skylighter: ... to fill the mill jar half full, ...

Mill (grinding) WikipediaBall mill. A typical type of fine grinder is the ball mill. A slightly inclined or horizontal rotating cylinder is partially filled with ...

excessive presence of ball scats. The balls are of the cast semisteel ... The ball load in the mill, prior to the removal of the scats, was calculated

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Optimization of mill performance by using online, how to fill in a ball mill,draw, and product grind size from the circuit Each of these performance parameters ...

how to fill in a ball mill A Method to Determine the Ball Filling, in Miduk Copper, how to fill in a ball mill,A Method to Determine the Ball Filling, in Miduk ...

Frequently Asked Questions About Planetary Ball Mill how to fill in a ball mill,1 Can planetary ball mill grind particles to the size smaller than 01 micron?

calculation of ball mill fill level – Grinding Mill . calculation of ball mill fill level 8599 Ratings ] The Gulin product line, consisting of more than 30 ...

Frequently asked questions about planetary ball mills. how to fill in a ball mill We have customers using our planetary ball mills grinding particles to submicrons..

how to fill in ball mill how to fill in ball mill . Flotation Machine. Hammer Crusher. HJ Series Jaw Crusher. and the first ball mill I ...

Industry News...the filling level of coal in a ball mill. The method for verifying the filling level in a ball mill fed by material which is to be ground and provided ...

WhatsApp)

WhatsApp)